Walk onto any jobsite on a Monday morning and you can tell within five minutes whether the electrical plan is going to help the schedule or sink it. The trucks are parked tight, ladders are staged, conductors are labeled, and the foreman already has the inspector on the calendar. That’s the difference a seasoned electrical contractor brings. The work is invisible when done right, but costs time and money when it isn’t. If you’re weighing whether to bring in a professional or let a handyman “handle the simple stuff,” this guide spells out the trade-offs with stories from the field and practical detail, anchored by what we see every week at American Electric Co.

What an Electrical Contractor Really Does

People hear “electrician” and picture outlets, lights, and a toolbox. An electrical contractor is that and much more: a licensed business entity that designs, installs, manages, and services electrical systems. On a single project, an electrical contractor like American Electric Co is juggling load calculations, utility coordination, permit packages, safety plans, submittals, parts procurement, inspections, commissioning, warranties, and preventive maintenance scheduling. The electrician on your job is the craftsperson you meet and trust in your home or facility. The contractor ensures that craftsperson is supported with the right plans, parts, and processes.

If you’ve never seen the backend, consider a simple service upgrade from 100 amps to 200 amps in an older home. American Electric Co standby generator installation The visible work is a new panel and mast. The invisible work includes verifying conductor sizes and temperature ratings, calculating existing loads and future expansion, coordinating a cutover with the utility, pulling a permit, arranging a temporary power plan for your fridge and furnace, labeling circuits, and documenting torque values on lugs per the manufacturer. That’s a weekday for an American Electric Co electrician with a competent project manager behind them.

Where Homeowners Save Money By Hiring Right

Electrical projects punish shortcuts. The cost of doing it twice usually exceeds doing it right once, especially when drywall, finish carpentry, or equipment downtime is involved. We see three recurring situations where a homeowner saves by calling a licensed pro early.

First, remodels that move kitchens or bathrooms. Appliances with heating elements, ventilation, and wet locations add code complexity quickly. Running a new microwave circuit sounds modest until we discover a loaded panel, undersized feeder, and four bootleg neutrals stuffed under one lug. Correcting those legacy issues safely requires judgment and experience. We’ve rescued more than one flipped-kitchen timeline by building a temporary subpanel to keep the house powered while we rework the main.

Second, EV charging. Most Level 2 chargers want a 40 to 60 amp circuit. The quick answer is “add a breaker,” but the honest process is a load calculation and often a panel strategy: derating, a smart load management device, or a service upgrade. We’ve installed EV circuits in condos with no spare breaker capacity by using listed load control devices that shed the car charger when the range is active, keeping the total amperage under the service rating. That avoids a five-figure service upgrade and satisfies inspectors because it’s a listed solution.

Third, old aluminum branch circuits. Homes built in certain decades used aluminum wire on 15 and 20 amp runs. Splices and terminations need specific devices and techniques to mitigate creep and oxidation. Replacing every run is ideal but rarely practical. A measured approach is to pig-tail outlets and switches with approved connectors and antioxidant compound, paired with CO/ALR or AL/CU rated devices. It’s not glamorous work, but it solves heat-related failures that otherwise become scorched insulation behind a plate.

The Commercial Logic: Downtime Costs More Than Labor

A store with the lights off at 4 p.m. on a Saturday loses revenue in minutes. A data room with a tripped UPS battery breaker risks servers. Industrial lines risk throughput when a VFD faults because someone grounded a shield at both ends. For commercial clients, the case for an electrical contractor is simple. You are buying risk reduction and uptime.

American Electric Co builds projects around load priority and fail-safe behavior. In a dental clinic, we segmented lighting circuits so the operatories stay lit even if a common area breaker trips. In a restaurant, we labeled convenience outlets separately from refrigeration, then tied refrigeration to a monitored circuit with a text alert. During a storm that took out half the grid, that alert saved thousands in spoiled inventory because the manager knew to start the generator and move perishables.

In facilities with sensitive gear, our teams test voltage imbalance and harmonics under real load. If your panels are serving nonlinear loads like LED drivers and computer power supplies, your neutrals can carry more current than your hots. We see neutrals run hot, bus bars heat stain, and nuisance trips that look like ghosts until someone meters THD and corrects it with better distribution or a K-rated transformer. This is normal work for an electrical contractor, not a surprise mystery.

Safety Is a System, Not a Slogan

Mains voltage does not forgive. The path to ground only needs your fingertip and a concrete floor to complete a circuit. People get hurt when small choices stack up: the wrong breaker type, a shared neutral on a multi-wire branch circuit without a handle tie, a bootlegged ground, a rusted service bond, a missing GFCI on a sump pump.

We treat safety as a workflow. American Electric Co electricians perform lockout-tagout on panels and gear, verify absence of voltage with a two-pole tester, and wear PPE based on available incident energy. Our teams maintain torque logs because a loose lug doesn’t always look loose. We photograph terminations and include them in closeout packages, so there’s a record of how the system left our hands. That attention prevents the “mystery arc flash” that happens when a panel warms and cools for a few seasons.

There’s another layer of safety that rarely gets mentioned: protecting your structure’s fire insurance. Adjusters look hard at origin points and whether work was performed to code. A signed permit, inspection, and invoice from a licensed contractor protects you in ways a cash job never will. We’ve been called for post-incident inspections where the savings from a DIY tie-in evaporated under deductibles and exclusions.

Permits, Code, and Inspectors: How Projects Stay Smooth

Permitting feels like bureaucracy until you see how much smoother a job runs when the inspector is looped in early. We handle load calculations, one-line diagrams, and panel schedules, then present them in the format your city’s plan desk expects. That saves weeks. Inspectors appreciate clarity and responsiveness. Give them labeled conductors, device cut sheets, and access to terminations, and they move fast.

Codes evolve. The National Electrical Code updates every three years, and local jurisdictions adopt at their own pace with amendments. GFCI and AFCI requirements have expanded. Tamper-resistant receptacles are standard in many areas. Grounding and bonding rules trip up even experienced builders when metallic paths like CSST gas lines or pool bonding grids are involved. An electrical contractor American Electric Co trains for these changes constantly, so the team can give you a simple answer in the field while backing it with chapter and verse.

One anecdote from a multifamily rehab: the plans called for meter stacks in a mechanical room with limited clearance. A quick sketch satisfied the architect. The inspector, rightly, flagged working clearances on the front and sides that the sketch missed. Because we had already coordinated with the utility, we moved the stacks to an exterior wall and shifted feeders. Schedule hit was 48 hours, not 4 weeks. That only happened because the paperwork and relationships were already in place.

Design-Build vs. Plan-Spec: Picking the Right Delivery

Some projects benefit from a design-build electrical contractor. We work with the client and architect from concept through commissioning, value-engineer materials, and make field decisions that fit budget and schedule without sacrificing safety. Other projects are plan-spec, where an engineer stamps a design and contractors bid to that spec.

We like both models. The key is choosing based on risk and complexity. If you are converting a warehouse into light manufacturing with compressed air, exhaust, and new equipment, design-build lets us lay out conduits and panels with equipment growth in mind. We can route power drops overhead to stay off the floor and tag each circuit by machine ID, so your maintenance team can isolate issues fast. On a public project with strict funding guidelines, plan-spec gives everyone a level field. A contractor who respects the spec and communicates alternates transparently can still save you money. American Electric Co often submits alternates for lighting control packages or gear with long lead times, detailing cost and schedule effects so you can decide with your eyes open.

The Materials Matter More Than You Think

Look behind a neat faceplate and you’ll see the choices that separate good installs from headaches. Copper vs. aluminum conductors, THHN in EMT vs. MC cable, spec-grade receptacles vs. residential devices, stranded vs. solid conductors on terminations, anti-oxidant on aluminum, proper ferrules on fine-strand control wire. These aren’t vanity upgrades.

We replaced 28 failed receptacles in a busy coworking space because the original installer used low-cost residential devices. Cleaners pull vacuums out by the cord, startups plug in space heaters, and contacts heat up. A modest step up to spec-grade with stronger springs and back-wire clamps cut replacement calls to nearly zero. That is pennies per outlet up front and hours saved down the line.

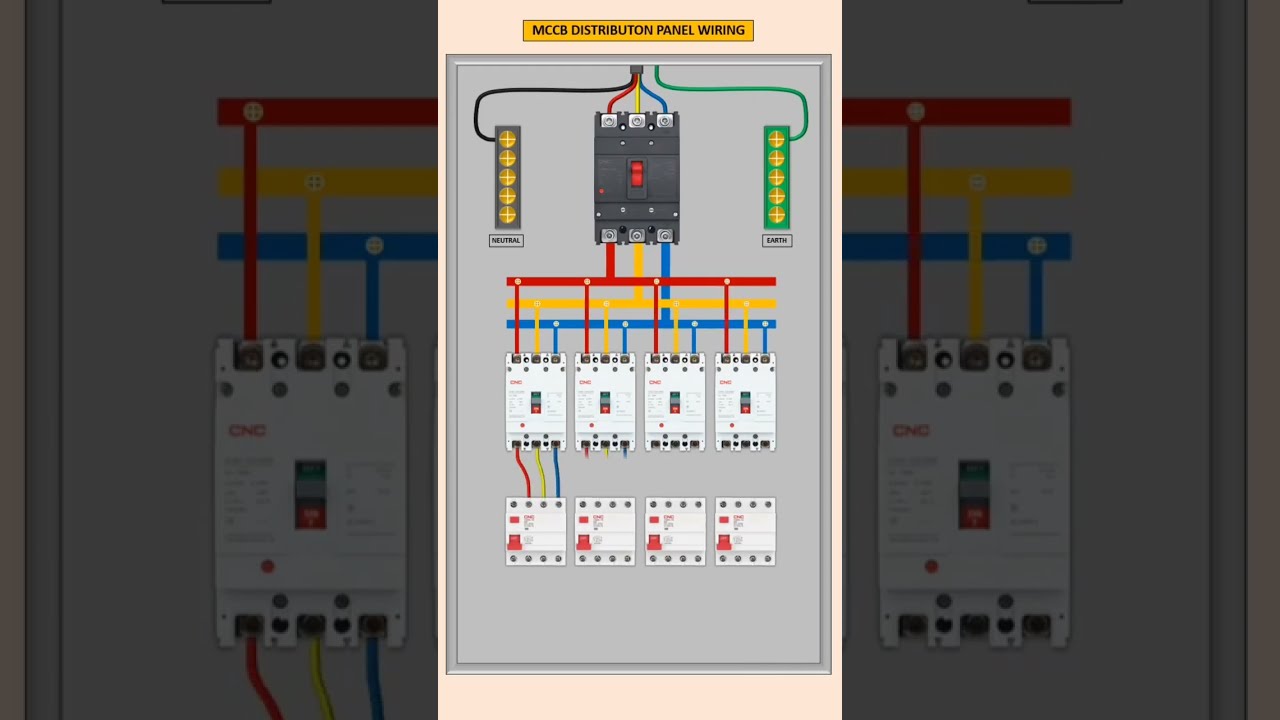

The same logic applies to panels and breakers. Mixing breaker brands to “make it fit” is a code violation unless listed for the panel. We open panels weekly with mixed breakers and no documentation. The risk is that thermal and mechanical trip curves don’t behave as designed, leading to nuisance trips or, worse, failures to clear faults. A professional electrician has the part catalog at hand and the patience to source the right breakers or swap a panel when the economics make sense.

Energy, Lighting, and the Real Numbers Behind “Efficiency”

Energy savings get oversold in glossy brochures. The math still favors LEDs, occupancy sensors, and daylight harvesting in most commercial spaces, but the honest question is payback period and maintenance burden. We ran a retrofit for a 40,000 square foot office with 2-by-4 troffers. The original proposal promised a three-year payback. After we modeled hours of use, actual utility rates, and a realistic failure curve for drivers, the payback landed at 3.8 to 4.2 years. Still good, but the client appreciated the honest range.

Lighting control systems are another place where right-sizing matters. A full networked control with BACnet integration sounds great until you discover you need a service contract to change schedules. In a law firm with fixed hours, we specified stand-alone room controllers with vacancy sensors and local dimming. The facilities manager can reprogram without a laptop. In a hospital wing where schedules shift, we chose a centralized networked system and trained their staff. Picking the right tool keeps your maintenance team from calling us at 10 p.m. to turn the lights back on.

For homes, a similar lesson applies. Whole-house smart systems can be wonderful, but a simple, reliable circuit with a high-quality dimmer is often the better choice in rooms where anyone, guests included, should understand the controls at first glance.

When Speed Matters: Emergency Calls and Temporary Power

Outages do not politely wait for business hours. During last summer’s storm run, our crews rolled at 2 a.m. to stabilize a senior living facility running on a portable generator. The transfer switch had failed. We installed a listed interlock on the main, brought in a properly sized rental generator with cam-locks, load-shed nonessential circuits, and got the building safe and cool before dawn. Over the next two days, we replaced the switch, tested transitions under load, and documented everything for the state inspector.

The lesson: preparation beats heroics. American Electric Co maintains a stock of temporary power gear, spider boxes, cord sets, and cam-lock assemblies, along with relationships with rental houses. We also stage materials for common failures like failed main breakers, cooked lugs, or lightning-damaged surge protection devices. If you operate a facility where downtime hurts, ask your electrical contractor to survey critical systems ahead of storms. A one-hour walkthrough and a short list of serial numbers can save six hours in the dark.

How To Vet an Electrical Contractor Without Guesswork

You don’t need to be an engineer to choose well. Ask pointed questions and look for practical answers.

- License and insurance: Request license numbers, liability, and worker’s comp certificates. Verify them online in your state’s portal. Scope and documentation: Will you receive a written scope, part numbers, and as-built drawings or photos? Good contractors build paper trails that protect you. Team and schedule: Who will be on site? What is the communication plan for change orders and inspections? Names and timelines beat vague promises. Parts strategy: How do they handle long-lead gear? Lead times on panels and switchgear can run 8 to 30 weeks. A real plan includes temporary measures. Warranty and service: What is covered, for how long, and who performs warranty work? If something trips at 7 p.m., will they answer?

If an American Electric Co electrician visits your site, they will welcome these questions. Good contractors are proud of their process. The answers should sound specific, not rehearsed.

The Hidden Work That Prevents Service Calls

There is a rhythm to a clean installation. Conductors are cut to length so the panel looks like a comb, not a bird’s nest. Arc-fault and ground-fault breakers are segregated from motor loads that can cause nuisance trips. Low-voltage cabling is kept at least six inches from power, crossing at right angles to reduce interference. Conduit fill is calculated so pulling wire does not nick insulation. Those details prevent callbacks.

We also invest in test gear that the average handyman doesn’t carry. Infrared cameras reveal hot spots at lugs. Power quality analyzers chart voltage sag during equipment starts. Insulation resistance testers catch compromised runs before they fail under load. On a school project, IR scans found a main lug warming 20 degrees above ambient under partial load. A half-turn with a torque wrench solved a future outage.

Renovations and Additions: Respecting the Existing Conditions

Every old building has a personality. You open a wall and find knob-and-tube spliced to cloth-insulated cable wrapped in friction tape. Or a metal box with no bonding jumper to the EMT. Respecting these conditions means choosing methods that upgrade safety without ripping out entire sections unnecessarily.

We favor transitional fixes that are legal and durable. For example, when extending a circuit from a junction of mixed methods, we terminate into a new, properly bonded box, isolate new work from questionable old work, and document it. In kitchens with shallow backsplashes, we use shallow-depth boxes paired with spec-grade devices to maintain cubic inch requirements while keeping tile work pristine. In plaster walls, we cut with oscillating tools and vacuum ports to keep dust down, then use repair rings for clean device mounting. These are small touches. They matter when you live with the results.

The People Side: Communication Makes or Breaks Projects

Electrical work touches multiple trades. Framers block for panels and equipment. HVAC techs need power and control. Plumbers need clearances around electrical gear. Quiet coordination prevents rework. Our foremen attend site huddles, call out interferences early, and keep a daily log of constraints. On a recent TI, we shifted a conduit run two bays after the ceiling grid made our original route impractical. Because we flagged it before drywall, the schedule didn’t slip and nobody argued over who pays to cut and patch.

With homeowners, we try to schedule around life. If your baby naps at 1 p.m., we plan the loud work for the morning and test circuits gently in the afternoon. We leave a clean site each day. You shouldn’t find wire scraps in the driveway or gypsum dust on your couch. Professional pride shows up in small courtesies.

What You Can Do Before the Electrician Arrives

You can help your project go faster and cheaper with a little prep.

- Clear access to panels, attics, crawl spaces, and equipment rooms. A straight path saves time and reduces risk. Gather appliance model numbers and desired locations. Knowing amperage and cord types prevents a second visit. Decide on finishes like device color and trim before rough-in. Changing from white to black after trim-out is more expensive than it seems. Share your future plans. If you want a hot tub next year, we can size conduit now and leave a pull string. Ask about temporary power or dust control if you’re staying on site. A homeowner who understands shutdown windows is a partner, not a bystander.

That short list shaves hours and avoids surprises.

When DIY Makes Sense, and When It Doesn’t

Plenty of capable homeowners can replace a light fixture, swap a standard switch for a dimmer rated for the load, or install a ceiling fan in a properly supported box. The moment you touch a panel, run new circuits, modify grounding, or tie into aluminum wiring, you should pause. The risk isn’t just shock. It’s long-term heat, hidden arcs, and insurance exposure.

For small tasks, we’re happy to coach. American Electric Co sometimes offers a walkthrough service where a licensed American Electric Co electrician spends an hour tagging your panel, explaining which breakers feed which rooms, and advising on safe maintenance like replacing batteries in interconnected smoke alarms. That small investment makes you safer and makes our future service calls faster because the panel is already mapped.

Why American Electric Co

You have choices. So why call us? Because we treat each job like it is our name on the panel cover for the next decade. Our teams balance field pragmatism with engineering rigor. We carry the specialty tools, the torque screwdrivers, the megohm meters, and the patience to use them. Our office staff knows permit desks by first name. We give you schedules we can meet and update you when conditions change. If something is wrong, we own it and fix it. That culture didn’t happen by accident. It came from years of jobs where doing it right kept the lights on for families and businesses that trust us.

An American Electric Co electrician working under our license brings that mindset to your door. You will see it in the way we lay out a panel, protect a floor, label a conductor, and leave a site. You will hear it in clear explanations and options with costs attached. You will feel it when your project moves forward without drama.

If your next step is an EV charger, a kitchen remodel, a tenant improvement, or a facility upgrade, bring in an electrical contractor American Electric Co early. We’ll help you frame the scope, identify the hidden gotchas, and build a plan that respects your budget, schedule, and safety. Electricity is unforgiving, but good planning and solid craft make it look easy. That’s our job.

American Electric Co

26378 Ruether Ave, Santa Clarita, CA 91350

(888) 441-9606

Visit Website

American Electric Co keeps Los Angeles County homes powered, safe, and future-ready. As licensed electricians, we specialize in main panel upgrades, smart panel installations, and dedicated circuits that ensure your electrical system is built to handle today’s demands—and tomorrow’s. Whether it’s upgrading your outdated panel in Malibu, wiring dedicated circuits for high-demand appliances in Pasadena, or installing a smart panel that gives you real-time control in Burbank, our team delivers expertise you can trust (and, yes, the occasional dad-level electrical joke). From standby generator systems that keep the lights on during California outages to precision panel work that prevents overloads and flickering lights, we make sure your home has the backbone it needs. Electrical issues aren’t just inconvenient—they can feel downright scary. That’s why we’re just a call away, bringing clarity, safety, and dependable power to every service call.